USC Fire Safety conducts Maximum Allowable Quantity (MAQ) assessments for USC research labs – one at a time – on an ad hoc basis or when the Fire Department requests them. For new lab construction or renovations, MAQ assessments must be built into the Facilities Planning & Management (FPM) project scope.

This will require a 10-week lead time for USC Fire Safety to conduct the MAQ assessment.

Environmental Health & Safety will provide baseline chemical inventory data, Fire Safety and FPM will verify control areas, and Fire Safety will be the point person and coordinator for MAQ assessments.

To request a MAQ assessment and requirements, please email: firesafety@usc.edu

MAQ Frequently Asked Questions

A control area is a space withing a building where hazardous materials are stored, dispensed, used or handled. Control areas are constructed with features like fire rated walls that prevent the spread of fire to and from other areas in the building, allowing for safe emergency egress and fire department response.

Determining MAQs is complex and relies on several structural and operational factors.

The most common factors that determine MAQs at USC are:

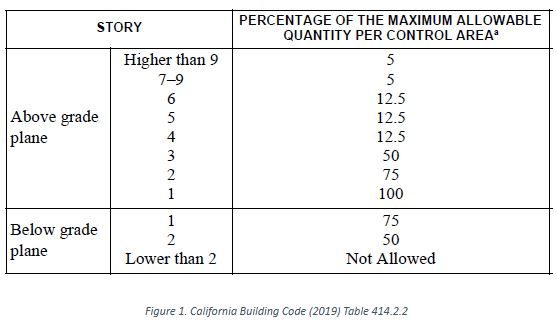

► on which floor your lab is located (see Fig. 1 below)

► whether a fire sprinkler system is installed throughout the building

► use of approved storage cabinets

As emergency response and egress become increasingly difficult with building height, the quantity of hazardous materials that can be safely used and stored decreases. For example, the MAQs on floors 7th and above are 5% of those allowed on the 1st floor. Conversely, if the entire building is equipped with a sprinkler system and approved storage cabinets, the MAQs may be increased.

See table below for the most common chemicals in each hazard category.

|

Hazard Class |

Common Chemicals |

|

Flammable Liquids IA |

Diethyl ether, 2-methylbutane |

|

Flammable Liquids IB/IC |

Ethanol, isopropanol, methanol, acetone, acetonitrile, xylenes |

|

Corrosive Liquids |

Acetic acid, hydrochloric acid, bleach, sulfuric acid, trifluoroacetic acid, cell lysis solutions (TRIzol, phenol/chloroform, etc) |

|

Corrosive Solids |

Sodium hydroxide, sodium dodecyl sulfate, paraformaldehyde |

|

Toxic Liquids |

2-mercaptoethanol, acetonitrile, acrylamide solutions, chloroform, formaldehyde solutions, cell lysis solutions (TRIzol, phenol/chloroform, etc), xylenes |

|

Toxic Solids |

Paraformaldehyde, EDTA disodium salt dehydrate, DL-dithiothreitol (DTT), phenylmethylsulfonyl fluoride (PMSF) |

|

Highly Toxic Liquids |

2-mercaptoethanol, acetic anhydride, hygromycin B solution |

|

Highly Toxic Solids |

Sodium azide, N, N’-dicyclohexylcarbodiimide (DCC), N-lauroylsarcosine) |

|

Oxidizer 2 Liquids |

Hydrogen peroxide solutions 8-35% |

|

Oxidizer 2 Solids |

Silver nitrate, potassium permanganate, potassium dichromate, sodium nitrate |

|

Oxidizer 3 Liquids |

Hydrogen peroxide solutions 60-91%, 70% perchloric acid |

|

Oxidizer 3 Solids |

3-chloroperbenzoic acid (mCPBA), periodic acid, sodium periodate |